Copyright © 2010 YCH Group Co., Ltd. All rights reserved.

Visitor

Made In Thailand

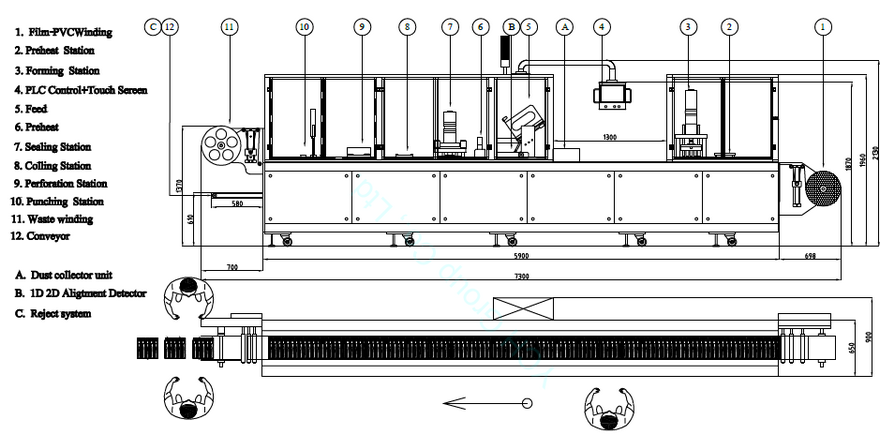

Gripper Chain Driven Blister card Packing Machine for consumer goods product.

YCH Auto blister packaging machine is flat type machine model driven by gripper chain . YCH Group is brand of Thailand origin for packing of consumer goods, cosmetic , electronic parts, auto part and more.. Machine designed for easily operate, quick setup, material save, easily maintain, strong. The machine feature consist of

- Machine design for medical equipment or medicine packaging, all flame part made from SS-400 and aluminum profile, Al5083, Al6063, Al7075, SUS304, and all part contact product use SUS316. All Aluminum part have anodize or hard anodize process for long time use.

- Main driven motor with overload protected (Torque limit by Amp.).

- Flat type blister packing machine forming station with compressor air blow form system. And combine between air blow and vacuum with plug.

- All status of machine show on HMI touch-screen 10.3” ,can adjust or control on HMI touch-screen.,Upper preheat, Lower preheat, Forming mold temp (cooling system temp.), Sealing station, Perforation station, Stroke distance ,Degree of working position

- All working station protect by Safety door alarm and machine stop

- Film exhausted alarm and machine stop.

- Alu foil exhausted alarm and machine stop.

- Back card exhausted alarm and machine stop.

- Waste torn alarm and machine stop.

- 3 EMG. stop button control panel, front and rear machine position.

- Driven motor speed control adjust on HMI touch-screen.

- Blowing forming time adjust on HMI touch-screen.

- All station machine moving by cam mechanism system.

- Film moving and stoke adjust on HMI touch-screen though to servo drive.

- Sealing pattern point knurling 0.6, 0.8, 1.0

- Buzzer alarm before automatic machine running.

- One minute forming, sealing mold change.

- Free space for label printing

- Heat and dust extraction system

- Discharge conveyer.

- PLC and HMI control system with arm swing style.

- 1 set of mold

- Sealing station up when machine stop.

- Edge trim station with hardness 60-65 HRC

Option Machine feature

- Label detector system.

- Photo mark sensor system.

- Reject or machine stop after detector

- Auto feeder

- Missing detector

Dimension of Machine

- length : Approx. 6500-mm.(255”-295")

- Width : Approx. 850 -1300mm.(33”-51”)

- Height : Approx. 1750-2250mm.(67”-88”)

- Control arm swing 825 mm.

- Weight : 1900 kg.

Foil specification

- Shell PVC thickness: 200-400um.

- Blister card thickness: 250-350mg.

- Max stroke transfer: 350mm

- Max Shell width: 430mm.

- Max forming area: 430 x 300 mm.

- Max PVC roll dia: 400mm

- Core dia: 70-76mm.

Technical data

- Method of operate : Manual or Auto

- Control system: PLC + HMI

- Drive system: Motor gear + Gripper Chain

- Transfer pvc: Servo drive

- Power: 220/380 50/60Hz. 3Ph 5

- Cooling water system: required

- Air pressure: required

- Smoke exhaust: required

- Productivity: 10-23 strokes/min